Large manual machines and CNC machines use toolholders that have been precisely ground with a male taper that mates with the machine s specific female taper. There is also a way to secure the toolholder in place with a pull stud or a draw bar thread. With CNC machines, the pull stud is more popular because it allows for easier automatic tool changing.

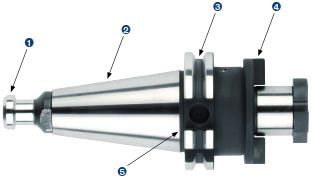

A toolholder consists of five basic components:

- Pull Stud

- Tapered Shank

- Gripper groove: circular groove

- Adapter

- Opposed Slot

Tapered shank

The standard defines six basic taper shank sizes including SK 30, SK 35,

SK 40, SK 45, SK 50, and SK 60.

The proper Taper Shank for the Type of Machine

ISO 60 Very large machines

ISO 50 Medium size machines

ISO 40 Small size machines

ISO 30 Very small machines

Coolant supply form AD/B | AD/AF

Toolholders form AD/B have internal coolant supply. To use form B (coolant

supply through the collar) the two headless screws must be removed and a

sealed pull stud must be inserted. To use form AD (central coolant supply)

the two headless screws must remain at the collar and a pull stud with drill

through must be inserted.

ISO 9270-2:2010 - 7/24 taper spindle noses for automatic tool changers -- Part 2: Dimensions and designation of spindle noses of forms J and JF

ISO 9270-2:2010 specifies the dimensions and tolerances of 7/24 taper spindle noses with tenons for automatic tool changers, intended for use with the corresponding tool shanks of forms J, JD and JF according to ISO 7388-2.

DIN 2079:1987-08 - Werkzeugmaschinen; Spindelköpfe mit Steilkegel 7 : 24

DIN 2079:1987-08 - 7/24 tapers for spindle noses for machine tools

Large manual machines and CNC machines use toolholders that have been precisely ground with a male taper that mates with the machine s specific female taper. There is also a way to secure the...

read more »

Close window

Steep taper

Large manual machines and CNC machines use toolholders that have been precisely ground with a male taper that mates with the machine s specific female taper. There is also a way to secure the toolholder in place with a pull stud or a draw bar thread. With CNC machines, the pull stud is more popular because it allows for easier automatic tool changing.

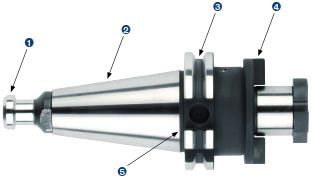

A toolholder consists of five basic components:

- Pull Stud

- Tapered Shank

- Gripper groove: circular groove

- Adapter

- Opposed Slot

Tapered shank

The standard defines six basic taper shank sizes including SK 30, SK 35,

SK 40, SK 45, SK 50, and SK 60.

The proper Taper Shank for the Type of Machine

ISO 60 Very large machines

ISO 50 Medium size machines

ISO 40 Small size machines

ISO 30 Very small machines

Coolant supply form AD/B | AD/AF

Toolholders form AD/B have internal coolant supply. To use form B (coolant

supply through the collar) the two headless screws must be removed and a

sealed pull stud must be inserted. To use form AD (central coolant supply)

the two headless screws must remain at the collar and a pull stud with drill

through must be inserted.

ISO 9270-2:2010 - 7/24 taper spindle noses for automatic tool changers -- Part 2: Dimensions and designation of spindle noses of forms J and JF

ISO 9270-2:2010 specifies the dimensions and tolerances of 7/24 taper spindle noses with tenons for automatic tool changers, intended for use with the corresponding tool shanks of forms J, JD and JF according to ISO 7388-2.

DIN 2079:1987-08 - Werkzeugmaschinen; Spindelköpfe mit Steilkegel 7 : 24

DIN 2079:1987-08 - 7/24 tapers for spindle noses for machine tools