ISO 26622-1

ISO 26622 has a secure 3-point contact, and can be used on multi-tasking, turning, rotating, and transfer machines in manual, semiautomatic, or fully automatic mode. KM can take advantage of a machine s fully automatic capabilities, like tool storage, and tool-handling, and signal-activated locking mechanisms, to dramatically improve machine.

Pre-balanced G 6,3 15.000 min-1

G 2,5 Fine balancing at extra charge

Material:

Alloyed case-hardened steel, tensile core strength of min. 800 N/mm².

Case hardened HRC 60 ± 2 (HV 700 ± 50), hardening depth 0.8 mm ± 0.2 mm,

black-finished and precisely grinded.

ISO 26622-1:2017

Modular taper interface with ball track system -- Part 1: Dimensions and designation of shanks

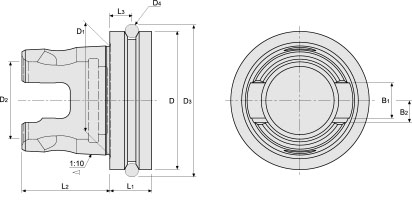

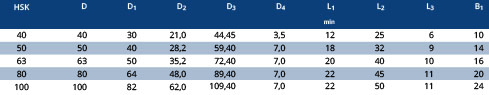

ISO 26622-1:2017 specifies the dimensions for modular taper interface with ball track system: tapered shanks for automatic and manual tool exchange to be applied on machine tools (e.g. lathe machines, drilling machines, milling machines and turn/milling machine centres). A range of shank sizes is specified and details of the coolant-sealing O-ring are specified in Annex A.

The shank incorporates a flange with a groove to enable automatic tool exchange. The tools can also be exchanged manually. The clamping of the shank can be realized by the use of locking balls of a standard size and by a variety of mechanisms.

The torque is transmitted at the tail end of the shank by friction, locking elements and keys.

ISO 26622-1 ISO 26622 has a secure 3-point contact, and can be used on multi-tasking, turning, rotating, and transfer machines in manual, semiautomatic, or fully automatic mode. KM can take...

read more »

Close window

ISO 26622-1

ISO 26622 has a secure 3-point contact, and can be used on multi-tasking, turning, rotating, and transfer machines in manual, semiautomatic, or fully automatic mode. KM can take advantage of a machine s fully automatic capabilities, like tool storage, and tool-handling, and signal-activated locking mechanisms, to dramatically improve machine.

Pre-balanced G 6,3 15.000 min-1

G 2,5 Fine balancing at extra charge

Material:

Alloyed case-hardened steel, tensile core strength of min. 800 N/mm².

Case hardened HRC 60 ± 2 (HV 700 ± 50), hardening depth 0.8 mm ± 0.2 mm,

black-finished and precisely grinded.

ISO 26622-1:2017

Modular taper interface with ball track system -- Part 1: Dimensions and designation of shanks

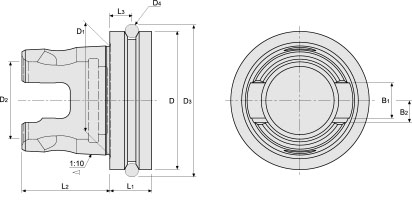

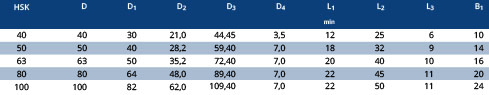

ISO 26622-1:2017 specifies the dimensions for modular taper interface with ball track system: tapered shanks for automatic and manual tool exchange to be applied on machine tools (e.g. lathe machines, drilling machines, milling machines and turn/milling machine centres). A range of shank sizes is specified and details of the coolant-sealing O-ring are specified in Annex A.

The shank incorporates a flange with a groove to enable automatic tool exchange. The tools can also be exchanged manually. The clamping of the shank can be realized by the use of locking balls of a standard size and by a variety of mechanisms.

The torque is transmitted at the tail end of the shank by friction, locking elements and keys.