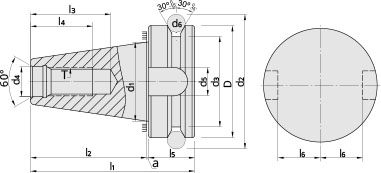

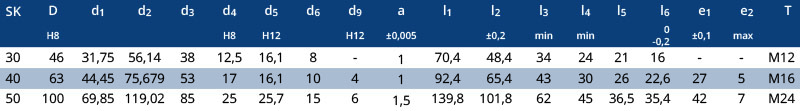

Toolholders similar ISO 7388-2

(ex. JIS B 6339 MAS 403 BT)

with Taper-Face [DUAL Contact]

Pre-balanced G 6,3 15.000 min-1

G 2,5 Fine balancing at extra charge

With internal coolant through the collar - form AD/B

Material:

Alloyed case-hardened steel, tensile core strength of min. 800 N?/?mm².

Case hardened HRC 60 ± 2 (HV 700 ± 50), hardening depth 0.8 mm ± 0.2 mm

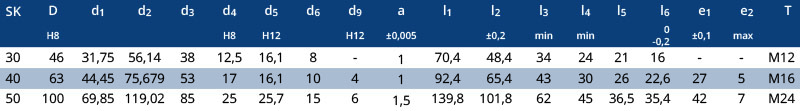

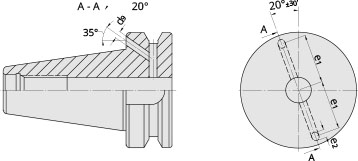

Form AD/B:

Delivery in form AD, type B closed with releasable headless screws.

Accuracy:

Quality of taper < AT 3 according to DIN 7187 and DIN 2080.

„Dual Contact"-Face tooling used on Taper-Face spindles achieve additional contact between spindle s face and holder s flange (vs. face/flange clearance with conventional steep taper fittings).

Advantages:

- Higher pulling forces (compared to classic spindles) achieve flange contact with pressure, complementary to the taper fitting.

- Higher rigidity particularly profitable to long tooling and machining in difficult materials.

- Higher run-out precision and axial (length) repeatability.

Taper-Face tooling can be used on conventional steep taper spindles but losing the face contact advantages.

Toolholders similar ISO 7388-2 (ex. JIS B 6339 MAS 403 BT) with Taper-Face [DUAL Contact] Pre-balanced G 6,3 15.000 min-1 G 2,5 Fine balancing at extra charge With internal coolant...

read more »

Close window

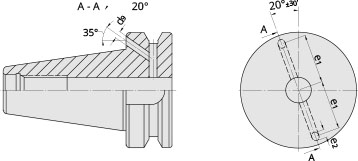

Toolholders similar ISO 7388-2

(ex. JIS B 6339 MAS 403 BT)

with Taper-Face [DUAL Contact]

Pre-balanced G 6,3 15.000 min-1

G 2,5 Fine balancing at extra charge

With internal coolant through the collar - form AD/B

Material:

Alloyed case-hardened steel, tensile core strength of min. 800 N?/?mm².

Case hardened HRC 60 ± 2 (HV 700 ± 50), hardening depth 0.8 mm ± 0.2 mm

Form AD/B:

Delivery in form AD, type B closed with releasable headless screws.

Accuracy:

Quality of taper < AT 3 according to DIN 7187 and DIN 2080.

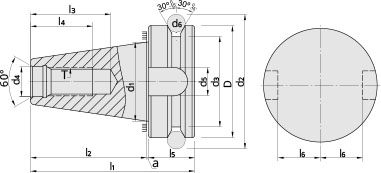

„Dual Contact"-Face tooling used on Taper-Face spindles achieve additional contact between spindle s face and holder s flange (vs. face/flange clearance with conventional steep taper fittings).

Advantages:

- Higher pulling forces (compared to classic spindles) achieve flange contact with pressure, complementary to the taper fitting.

- Higher rigidity particularly profitable to long tooling and machining in difficult materials.

- Higher run-out precision and axial (length) repeatability.

Taper-Face tooling can be used on conventional steep taper spindles but losing the face contact advantages.